The waste management industry plays a crucial role in protecting public health and the environment by safely handling, treating, and disposing of a wide variety of waste streams-municipal solid waste, water treatment residuals, industrial by-products, and hazardous wastes. This sector supports sustainable development by minimizing pollution, recovering resources, and complying with stringent regulations.

Given the diverse waste types and complex regulatory landscape, waste management companies face ongoing challenges in ensuring safety, environmental compliance, and operational efficiency. Advanced technology solutions that streamline Environmental, Health, and Safety (EHS) management are essential to meet evolving regulations and mitigate risks effectively.

Emerging trends, such as the adoption of AI and automation, are helping companies manage safety, reduce incidents, and improve environmental performance. Technology-driven EHS platforms are empowering companies to integrate real-time monitoring, risk assessments, and compliance reporting to ensure both safety and sustainability. Given these challenges, adopting a comprehensive EHS management system is not just a regulatory requirement but a competitive advantage.

The waste management industry is subject to rigorous regulations to ensure worker safety, environmental protection, and product quality. Key regulations include:

RCRA (Resource Conservation and Recovery Act):

Mandates cradle-to-grave hazardous waste tracking, storage, and disposal standards.

Occupational Safety and Health Administration (OSHA): Establishes safety standards to protect workers from hazardous wastes and ensure safe working conditions in processing plants.

Environmental Protection Agency (EPA) Regulations: Sets guidelines for managing air and water pollution, hazardous waste, and chemical disposal, aiming to minimize environmental impact.

CERCLA (Superfund): Governs cleanup of contaminated sites, holding polluters financially liable

Compliance with these regulations is essential to avoid penalties, protect workers, and minimize environmental damage. They also help waste management facilities improve operational efficiency, reduce risks, and enhance product quality, ensuring long-term sustainability and a strong reputation in a highly competitive and regulated industry.

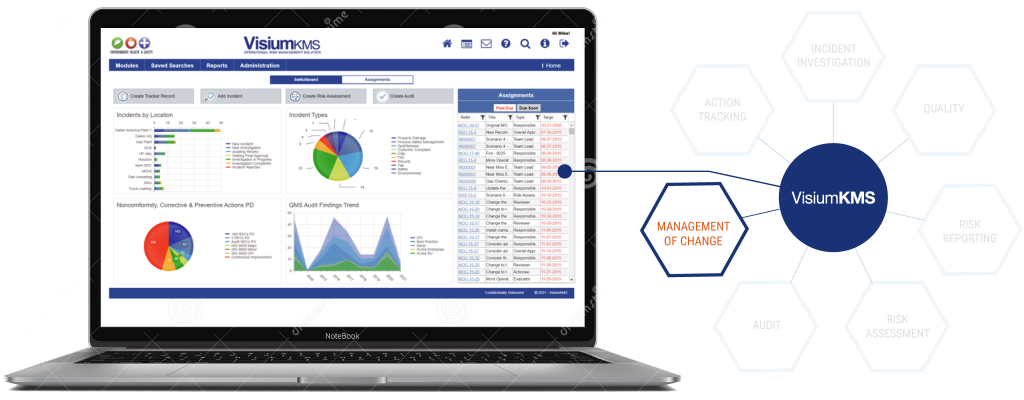

VisiumKMS offers tailored solutions to streamline EHS operations, reduce risks, and help oil and gas companies thrive in a challenging, regulated environment. Here is how each module can support your business.

Use Case: The Tracker module enables organizations to meticulously monitor the status and compliance of critical safety equipment, waste containers, and inspection schedules. For example, waste management companies can track hazardous waste storage containers’ inspection dates and chemical inventories to ensure regulatory compliance with EPA and OSHA standards. This prevents overdue inspections and reduces the risk of environmental incidents or regulatory fines by providing real-time alerts and centralized documentation

Use Case: The Risk module facilitates comprehensive risk assessments across waste handling, treatment, and disposal operations. It helps identify potential hazards such as chemical exposures, equipment failures, or environmental releases. Waste management firms can prioritize risk mitigation efforts based on severity and likelihood, enabling targeted controls that reduce workplace incidents and environmental impacts. For instance, a landfill operator can use the module to assess leachate seepage risks and implement corrective actions before contamination occurs

Use Case: This module streamlines the reporting, investigation, and root cause analysis of incidents including spills, exposures, near misses, and injuries. Waste management companies can ensure timely and accurate documentation to meet OSHA and EPA reporting requirements. By analyzing incident trends and lessons learned, organizations can implement preventive measures that enhance safety culture and reduce recurrence. For example, a hazardous waste transporter can reduce spill-related fines by over 50% by leveraging this module’s investigation workflows

Use Case: The Quality and Corrective and Preventive Actions (CAPA) module manages deviations, non-conformances, and corrective actions related to waste processing and environmental compliance. It supports continuous improvement by enabling rapid identification of root causes and verification of corrective measures. For instance, a municipal recycling facility can reduce contamination rates and improve material recovery by systematically addressing process deviations identified through this module

Use Case: The Audit module supports planning, execution, and follow-up of compliance audits against regulations such as RCRA, OSHA, and local environmental standards. Waste management companies can generate detailed audit reports highlighting gaps and corrective actions, ensuring continuous regulatory compliance. For example, a water treatment plant can use the module to conduct EPA discharge permit audits, reducing violations and associated penalties

Use Case: Empowering employees to report safety observations and near misses in real time, the Observations module fosters a proactive safety culture. Waste management organizations can track and resolve potential hazards before they escalate into incidents. For example, frontline workers at an industrial waste facility can quickly report equipment malfunctions or unsafe conditions, enabling timely interventions that prevent accidents

VisiumKMS uses advanced AI agents to help your business stay agile in an ever-evolving regulatory landscape. Our AI-driven platform continuously adapts to changing business rules and regulations, ensuring compliance in real-time. By analyzing vast amounts of data, VisiumKMS AI agents help you transform raw information into actionable insights, empowering your team to make informed decisions. This proactive approach helps streamline operations, reduce risk, and enhance overall efficiency, keeping your business ahead of the curve.

Implementing VisiumKMS in the chemical manufacturing sector can lead to substantial financial gains by enhancing operational efficiency, ensuring compliance, and improving safety performance. Below are key areas where VisiumKMS can help organizations achieve a strong ROI:

1. Cost Savings through Operational Efficiency

Streamlined Operations: VisiumKMS automates manual EHS workflows such as compliance tracking, inspections, and reporting, significantly reducing labor and administrative costs.

2. Compliance and Risk

Reduced Compliance Costs: By centralizing compliance data and automating audit and incident management, VisiumKMS helps waste management organizations avoid costly fines and penalties

3. Enhanced Safety Performance

Incident Reduction: VisiumKMS’s incident and observations modules enable rapid reporting, investigation, and root cause analysis, fostering a proactive safety culture that reduces workplace accidents.

Example 01:

A waste recovery facility using AI-driven analytics saved £47,000 on a single batch of material by quickly identifying contamination and optimizing sorting processes, showing how automation directly improves the bottom line. Source

Example 02:

A hazardous waste transporter reduced spill-related fines by 55% through AI-powered risk identification and proactive employee hazard reporting.

Source

Example 03:

a landfill site reduced groundwater contamination incidents by 40% within six months by using predictive risk modeling and CAPA workflows to address leachate seepage risks

Source

ROI Benchmark

In the waste management industry, experts note that an ROI of over 14% is considered favorable due to the capital-intensive nature of operations. By leveraging VisiumKMS to streamline processes, enhance compliance, and improve safety, companies can achieve substantial financial returns while maintaining operational excellence.

VisiumKMS automates EHS compliance with regulations like OSHA, EPA, and REACH, reducing manual processes and minimizing the risk of fines. Our platform reduces manual processes and ensures real-time compliance monitoring, minimizing the risk of costly penalties and reputational damage. AI-driven insights help proactively identify and address potential risks in real-time.

Our advanced AI agents continuously analyze operational and compliance data to identify emerging risks, automate monitoring, and generate actionable insights. This proactive intelligence helps waste management firms prevent incidents, optimize processes, and adapt rapidly to changing regulations such as RCRA, EPA hazardous waste rules, and local environmental standards.

With VisiumKMS’s incident management tools, waste management sites can prevent accidents, reduce safety risks, and foster a proactive safety culture. With features such as hazard identification, real-time safety monitoring, and incident investigation, the platform helps create a safer work environment. The platform helps lower injury rates and associated costs while improving overall safety performance.

We collaborate with industry-leading companies and organizations that enhance our solutions, validate our capabilities, and ensure the highest standards in EHS management.